Container Loading Sepervision

Why do I need a Container loading supervision service :

More and more foreign purchasers buying products in China, but they receive products that are inconsistent with the actual orders, such as products that are inconsistent, poor quality, insufficient quantity of products, problematic containers, and even empty containers, resulting in great economic losses.

To avoid the above, we recommend that you use our container loading supervision (CLS) service. Sometimes we call it "container loading inspection". It takes place in the warehouse of the manufacturer or the business place of the freight forwarder.

In the process of supervision, we should not only supervise the correct loading and quantity of products, but also check the correct packaging and quality of goods.

What criteria are covered in a Container Loading Supervision?

We cover the following points during the Container Loading Supervision:

>Quantity and assortment

>Correct products

>Condition of containers

>Supervising proper loading

>Condition of export cartons

>Stopping loading in bad weather

>Shipping marks

Container Loading Procedure:

Our professional inspectors will come to the loading location in person to represent the interests of your company:

Inspection before container loading:

1. Record loading conditions (weather, container arrival time, container number, truck number, etc.)

2. Check the containers for damage, leaks, moisture, mildew, consistent container number printing, etc.

3. Check the goods before loading:

A. Is the product correct? Is it conform to the client’s requirements?

B. Is the product quantity sufficient? Is the quantity conform to the order and packing requirements?

C. Random select products to check whether the product quality is good? Meet the customer's requirements?

D. Is the package complete? Good?

Inspection during container loading:

1. In the process of loading, it is not allowed to use violence to load. It should be placed with care and according to the customer's requirements.

2. In the process of loading the container, we should count the number of products, not more or less.

3. At the beginning of loading, 1/4,1/2,3/4,4/4, carefully check the position and take photos.

4. After all the goods are loaded, check again whether the quantity is completely conform to the order, and check whether there are any goods left unfilled.

Inspection after container loading:

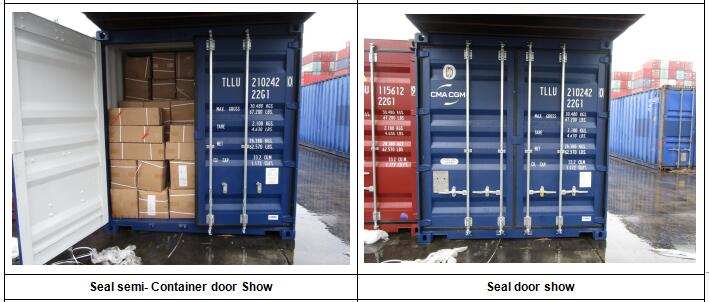

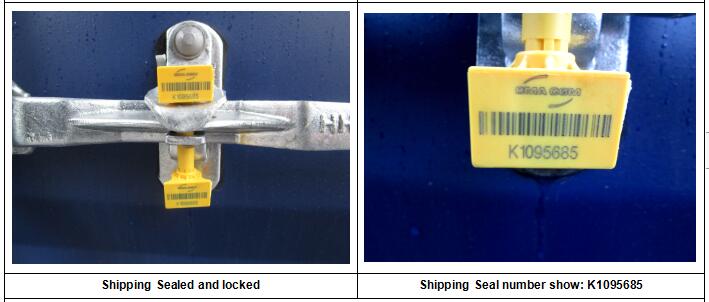

After checking that there is no problem, check the number of the cabinet lock. After checking that there is no problem, lock the container and make sure that it is completely locked. Take photos and record.

When is a suitable time to conduct a container loading Inspection?

A Pre-Shipment Inspection is suggested to be scheduled at least 2 working days before the planned loading date, so that the buyer can have enough time to check the report and decide whether to release the shipment as planned, or to discuss corrective actions with the manufacturer.

What is the cost of a loading Inspection?

Our standard all-inclusive inspection cost is 200 USD/man-day (no hidden fees) in any major manufacturing clusters in China.

Send Email

Send Email +8618929520552

+8618929520552